Roller sorters apply to installations that require the administration of the biomass in maximum of defined dimensions (e.g. briquette), and there is concern that the material supplied will not necessarily meet these requirements. They are to separate oversize items correct from the proper grain. Sorting occurs due to the movement of material between the rotating and spreading rollers. The desired material passes through the rollers, the elements that do not meet requirements are separated.

The sorters are supplied with electric drive. Power is transferred to the rollers via chain. Construction of a sorter is designed to protect the belt and chain drive against the ingress of dust.

Ecoenergia offers biomass roller sorters, where the spacing is pre-selected to meet customer’s needs. Typical performance of sorting is up to 30 tons of material per hour. There is a possibility of providing equipment in ATEX standards.

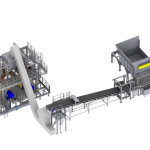

Ecoenergia Sp. z o.o., as part of its services, designs and prepares milling systems for biomass. Before choosing a device, we analyze the biomass available and on this basis, we recommend the most optimal arrangement in terms of needs.

The services provided:

- Analysis of biomass and equipment selection,

- Device delivery,

- Start-up,

- Auxilliary structures projects,

- Steel reinforced concrete structures projects,

- Assembly or supervision of installation.

A typical installation consists of two to four hammer mills with a capacity of 6 to 12 tons per hour each (depending on the required milling). The mills can be used for biomass in the form of pellets or briquettes pre-crushed in a crusher.